Safety Device

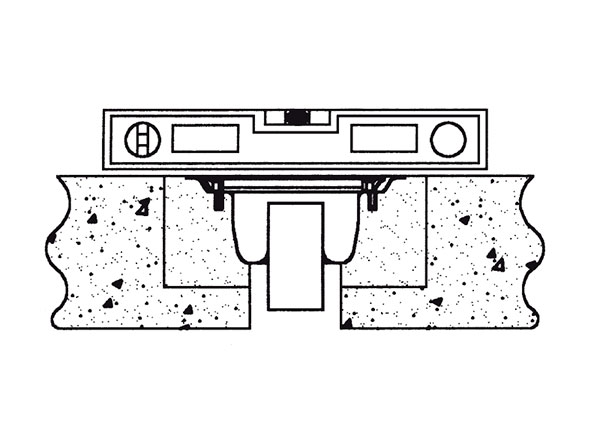

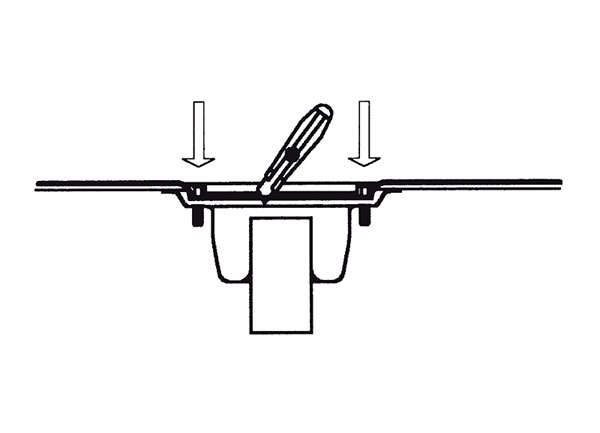

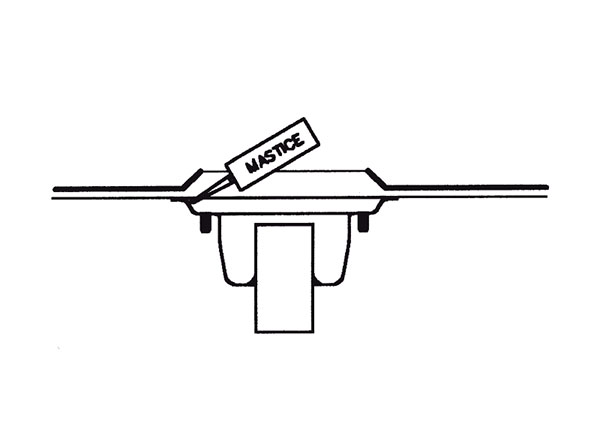

- Different models of interchangeable washers allow for future changes to the spaces such as extensions/alterations to the systems or equipment, thus facilitating the buildings refurbishment and providing more flexibility of use.

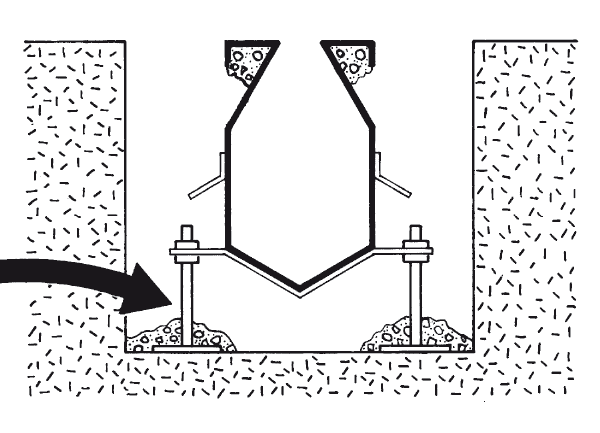

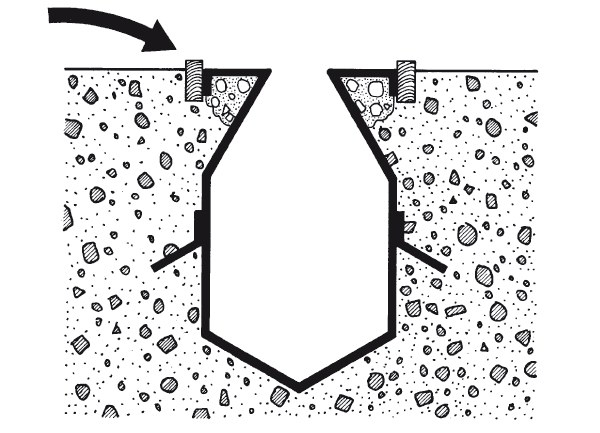

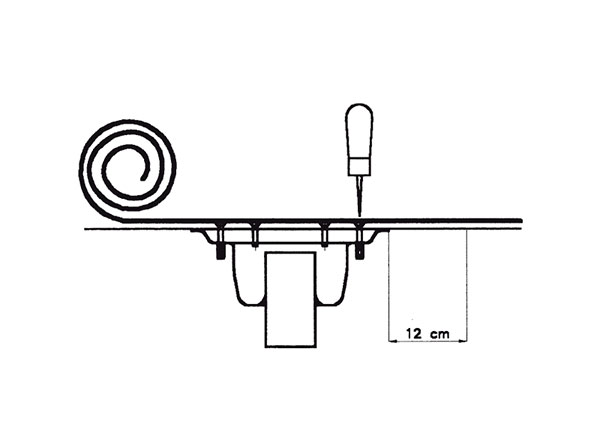

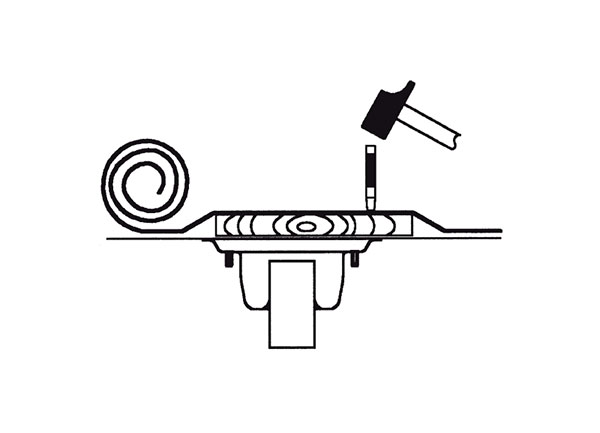

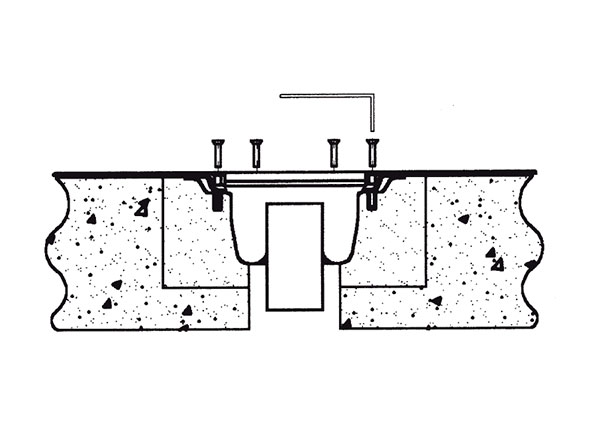

- Traps and drain gutters need to be in sufficient amount to collect storm water. Their location must be accurately chosen depending on the spaces and systems lay-out.

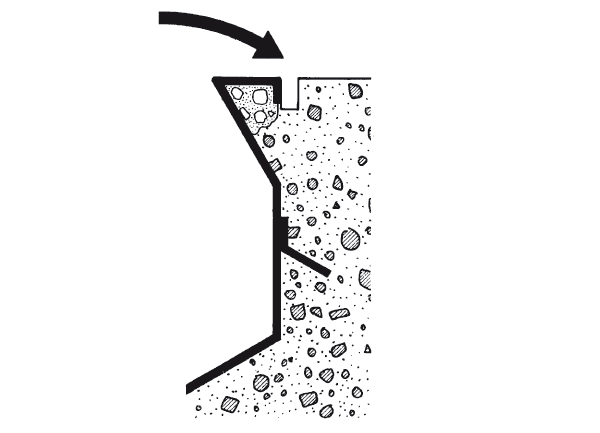

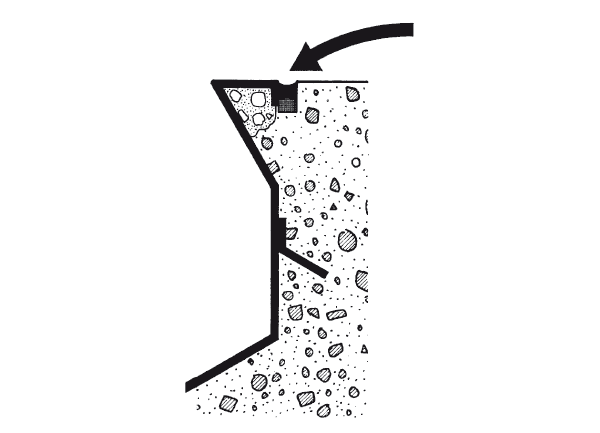

- To minimize the length of the water path and the stagnation of dirt – which is generally the first cause of contamination – the ideal layout should ensure easy and quick drainage of the washing liquid and a more economic use.